The Liquid Packing Machine for liquids is a quality offering that makes use of highly accurate IC controls to fill the pouches with right amount of liquid contents. We also offer customization on the machines for a variety of packaging unit sizes. Our packets come composed from quality material so that they survive the harshest of transport conditions and come in a good number of sheath thickness that provides strength.

It is widely used for packing various kinds of liquid. Such as pure water, milk, soybean milk, fruit juice, beverage, soy sauce, vinegar and wine. It uses single lay PE film for packaging material. It is automatic for ultraviolet radiation, sterilizing bag forming, code printing precisely filling, and synchronization with sealing and cutting. This series machines have been long-tested, and their performance gained a very high reputation from our clients because of the simple operation and smooth work with low failure rate.

Automatic liquid packaging machine can complete the whole process of film sterilization with ultraviolet radiation, date printing, rationed filling and sealing & cutting automatically as a continuous action. The finished package is beautiful and secure.

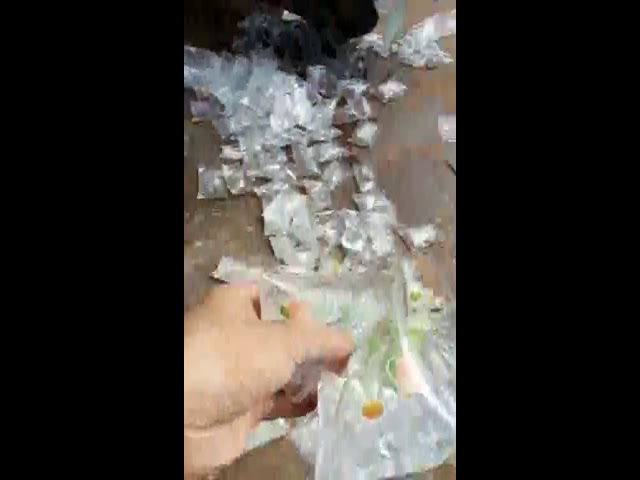

Liquid Packing Machine Show

Performance and features

1.wide applications: various state and nature of liquid & thick liquid;

2.A wide range of pouches: all kinds of pre-made pouches;

3.Easy to operate: PLC controller, HMI system makes easy operation;

4.Easy to adjust: change different pouches within 10 minutes;

5.High automation: unmanned in weighing and packing process, machine alarm automatically when failure;

6.Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost;

7.The product contact parts are adopted SUS304 stainless steel to ensure sanitation and safety, meet the GMP standard;

8.Imported engineer plastic bearings, no need to oil, no contamination;

9.Vacuum generator: low consumption, high efficiency, cleaness, and long useful life;

10.Waterproof design:direct water-washing the machine surface,easy to clean, prolong the useful life

11.Pre-made bag packing: perfect sealing quality, upgrade the finished product.

Technical parameters

| Equipment model | ZG8-200 |

| Equipment material | 304 stainless steel |

| Pneumatic component | SMC,AirTAC |

| Vacuum component | Vacuum generator (SMC) |

| Drive mode | Frequency conversion motor drive |

| Measuring type | Liquid filler, peristaltic pump, draw-off pimp |

| Operation interface | Touch screen(double language:Chinese and English) |

| Bag materials | Heat sealable film as PA/PE,PET/PE,AL film etc. |

| Bag size | W:70~200mm L:100~300mm (date coding requires≥140mm length) |

| Filling range | 5~1500g |

| Packing speed | 20~45bags/min (depended on the product and filling weight) |

| Package accuracy | Error≤±1% |

| Weight | 1000kg |

| Dimension | 1675*1535*1480(L,W,H) |

| Total power | 2.3kw |

| Driving power source | 380V Three-phase Five-line 50HZ |

| Control power source | DC24V |

| Compress air requirement | ≥0.45m³/min (compress air is provided by user) |

Iapack is the leading provider of inline liquid filling machines and liquid packaging machinery, offering a wide variety of packing machines with manual, semi-automatic and fully automatic functions. We have both gravimetric and volumetric liquid packing machines available for various industries from food and beverage production to industrial and corrosive product production.

Our electronic automatic packing machines range in size from portable table top machines to industrial size liquid packaging systems – whatever is needed to get your job done. View our liquid fillers below, and don’t hesitate to contact us for more information on our products.

When it comes to your liquid filling needs, rely on Iapack to help you determine the best packaging system for your business. Contact us today for a free consultation.

Gravity and Pressure packing machines

The Gravity and Pressure/Gravity packing machines are suitable for bottling virtually any water-thin to medium consistent viscosity liquid. Gravity packing machines are ideally suited for thin, foamy products where pressure/gravity packing machines handle heavier viscosity products.

Pump packing machines

Iapack offers several different types of pump packing machines to accommodate a wide variety of products. They provide an accurate and versatile method for filling low, medium and high viscosity liquids into a wide range of containers. Iapack uses a variety of pumps including progressive cavity pumps, gear pumps, lobe pumps, rotor pumps or whichever is best for the application. We work with each customer to choose the right pumps, valves, and fittings for each application.

Gravity, Pressure & Vacuum Overflow Bottle packing machines

Overflow packing machines provide the same cosmetic fill level, making them ideal for filling transparent containers that must have a consistent fill level. Gravity and pressure overflow fillers are designed to handle thin to medium viscosity products. The Iapack Vacuum Overflow Filler is used for specialty filling applications and is typically used to fill small volume glass containers with low viscosity liquids.

Piston packing machines

Piston packing machines are another great option for packaging liquids. They offer fast and accurate fill rates, versatility with the ability to handle many different types of products, and they’re gentle on products. They’re ideal for viscous liquids including batters, sauces, pastes, icing, chunky fillings, and certain aerated products. Generally, these liquid packing machines are used to fill liquids that are squeezed through pastry bags or similar packaging.

Iapack offers some of the best liquid packing machines available for products of all types. The versatility of our equipment makes them compatible with many different applications, depending on your specific system requirements.

Iapack manufactures a complete range of Sanitary packing machines to meet a wide variety of applications. All sanitary fillers are designed with quick breakdown fittings, valves and pumps to be used where needed. All reservoirs have flanged quick disconnect fittings so that the fillers can be easily and thoroughly cleaned.

Corrosive packing machines

Using 1/100 second timers on each individual fill head offers simple adjustment and extreme accuracy. The fillers are designed to fill from a fraction of an ounce to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids.

Molten packing machines

Iapack Molten packing machines are designed with an adjustable self-contained heating system, PLC operator controls, anti-drip/anti-foam nozzles and independent heating controls and those are just a few reasons why these molten fillers stand above the competition.

Applications:

Petroleum and automotive products

Cosmetic & personal care products

Household & industrial cleaners

Bottled water & still beverages

Acids & corrosive products

Candle & molten products

Pharmaceutical products

Paints, stains & sealants

Food products & sauces

Agricultural products

Flammable solvents