Our tea bag packing machine has been excellent engineers carefully study design, the use of microcomputer control of optical technology, high accuracy, fast, good quality, solve the traditional tea packaging tedious process. An automatic dosers several labor equivalent amount of tea production and tea shop is a good helper.

Tea is all extremely sensitive to exposure to air, light and environmental odours. The fragrance and flavour of coffees and teas are their core values and Iapack’s packaging solutions protect the quality and extend the shelf life of these products.

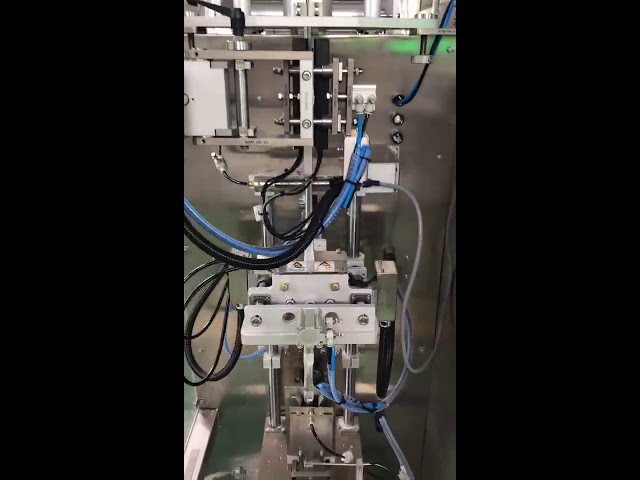

Developed over many years of experience in this industry, Iapack’s packaging machinery provides excellent hermetic sealing systems, special valve systems for freshness and reclosable systems for consumer convenience. Our proven know-how is expertly applied to our entire range of reliable, flexible and innovative packaging machinery and automatic lines designed with your needs in mind.

Iapack supplies tea packaging machines. A fully automated machine that can produce standard tea bags and triangular (pyramid) tea bags at a speed of 40 bags per minutes. The machine is equipped with a range of sensors for identifying any errors. A tea bag with sticky tape is automatically ejected, for example. This minimises the standstill time of the machine. As a result, you can keep the OEE up for over 91% of the total production time. The thread is also located in the top of the pyramid bag and not on the side as is the case for similar machines; this means that the bag keeps its attractive triangle shape.

Applications:

Tea Bag Packing Machine is a kind of machine used for packing tea seeds, medical, health-care and tea industries granular shaped ingredients. All of these items could be packed with both inner and outer envelops, and with thread and tag at the same time.

Tea Bag Powder Packaging Machines

Iapack design packaging machine for round tea bag, ideal for all powdery and granular products such as tea and coffee, periodically serviced and regularly checked for performance, so that all client expectations can be fully satisfied.

The machines used to package products of this type are tea packaging machines for single-portion sachets (heat-sealed on 3 or 4 sides) and stick packs formats, vertical or horizontally sliding (Series C3, CO, CS, DIVA and CG), capable of transporting packs over a conveyor belt to the final packing station.

These machines have a continuous high-speed rotary motion, and are versatile and easily maintained, complete with a high-precision volumetric batcher (specifically designed for every product type), a linear weigher and a packing unit capable of automatically scoring packs to facilitate opening for end users.

Technical Specifications

| capacity | 30-50bags/Min (Determined by packing material) |

| Filling precision | ≤±2% (Determined by packing material) |

| Bag size | 60-80(W)*40-80(L)mm |

| Packing film | 120mm,140mm,160mm |

| sealing type | Triangle bag and flat bag |

| Filling range | 2-10ml |

| film thickness | 0.04-0.06mm |

| Packing material | Nylon, Polyester net non-woven fabrics, ultrasonic sealing materials |

| Rolled outer diameter | ≤400mm |

| Rolled paper core inside diameter | 76mm |

| air consumption | 0.6Mpa 0.4m3/min |

| total power | 2.2KW |

| Power | Single 220V 50HZ |

| air compressor | less than 1 cube |

| Dimension | 780× 940×1800mm |

This machine is an automatic multi-functional tea bag packaging equipment with a new heat sealing type.

The inner bag and outer bag forming is finished at the same time,avoid direct contact with the packing macterial

and improve working efficiency.Inner bag is made of filter paper with thread and tag attached,and outer bag is made of composite paper.The biggest advantage is:tag attaching and outer bag making can adopt photoelectric positioning.

Features

Nylon triangle tea bag adopts the imported environmental nylon, weaving cloth material from Japan, which is of sense of high quality food class filter material without poison and bacteria, with heat-resistance approved by China safety inspection, the single color printing of pulling paper on packing is made from imported poison less ink from Japan suitable for food, and could100% recycle and reduce the environmental pollution. Of which the sealing take use of unique method-ultrasonic mark sealing, tight, sanitary, safety, reducing abundant sealing width, without wasting filter material, this plastic high quality sense of tea bag image is more natural and delicated fragrance compared with common tea bag, which is more beautiful and high level, and it is more easy for public to accept.

Comparing with common tea bag, this tea bag could extend itself quickly after immerse in hot water, preserving the original taste, delicate fragrance and natural, do not hurt tea bag, could immerse for many times, featuring the stout of material and it is not easy to tear off, the design of transparent net makes the taste of tea plays more completely, the consumer could see the appearance, smell the fragrance, look the color, taste and check tea with original taste just like the fresh tea, let the taste not restricted in container, you could enjoy more convenient modern life at any time and place. The choice of volume measurement, or electronic scales measuring,but different price

How to choose Tea Bag Packing Machine?

♦ Bag type: Just Inner Pyramid Teabag or with outer envelope?

♦ Packing Speed: Speed for inner bag and Speed for inner bag with outer envelope?

♦ Stability & Bag shape: Perfect Pyramid Bag Shape, and well sealed?

♦ Packing material: Machine can seal all Nylon, Non-woven fabric; PET; PLA; 100% biodegradable transparent material?

♦ Accuracy: Can reach up 0.1G when using Electric Weigher?

♦ Application scope: Packing scope includes from powder to big granules in one machine?

♦ Mixing packing: Can fill with different ingredient of required amount and finish pack, for example, 2.7 gram Tea + 0.3 gram Dry orange peel in one bag?

The Tea Packing Machine belongs to wide range of machinery and complete systems for weighing, dosing, packaging and palletizer that Iapack can offer. The skills and experience of our technical department guarantee customers personalised and specific solutions, capable of meeting all requirements.

Tea Packing Machine concerns and scenario

Tea is an important part of our daily life and it has a huge requirement in the retail segment. Its production is estimated at 1200 Million Tons annually. The significance of tea packing machine cannot be ignored. Tea packing machine is required to fulfill the high demand.

Tea and Green Tea both are very light in weight from a tea packing perspective and have a non uniform bulk density that may vary from lot to lot or within the lot also due to various factors.

The packed tea is sold in various denominations ranging from 25gms to 1kg. Manufacturers and packers, require a tea packing machine that can fill multiple nett weights in the same machine. As the bulk density of tea is not uniform, which causes variation in net weight if packed on the basis of volume. As the raw material costs increase it becomes more important to have a control over the net weight packed in each pouch.

If the weight is less then it leads to complaints from the market and may also have a legal implication, so manufacturers who face the problem of variation in weight tend to pack more in each pouch. As extra weight goes in each pouch it adversely affects the economics and erodes the profitability.